Caicheng Printing Is A Professional Custom Paper Boxes Manufacturer & Supplier Since 1996

Caicheng Printing Is A Professional Custom Paper Boxes Manufacturer & Supplier Since 1996

One of the most commonly used packaging solutions in today's world is corrugated boxes, which are used for the shipping of all kinds of products across the world, for shipping heavy items, shipping fragile items and much more. But despite being everywhere, many people don’t fully understand why these boxes are so incredibly strong.

Why corrugated boxes are the most common packaging for small businesses and large businesses alike? Later in this article, we will discuss the science and structure of corrugated box design and understand how it is so cost effective and durable.

Imagine this: You place an order for a fragile item, perhaps, online and it arrives perfectly in one piece, secured within the sturdy corrugated box that delivered it. Although it may look like just another box, its design boasts surprising strength. Corrugated boxes provide excellent protection due to their smart style and composition. These boxes offer unparalleled support and durability whether the products are moving, in storage, or shipping.

So why are corrugated boxes so reliable? Are they regular cardboard with a bunch of extra layers? Let's dig deeper into corrugated box design and uncover the exact reasons why businesses all around the world rely upon them to package things.

Understanding Corrugated Box Design

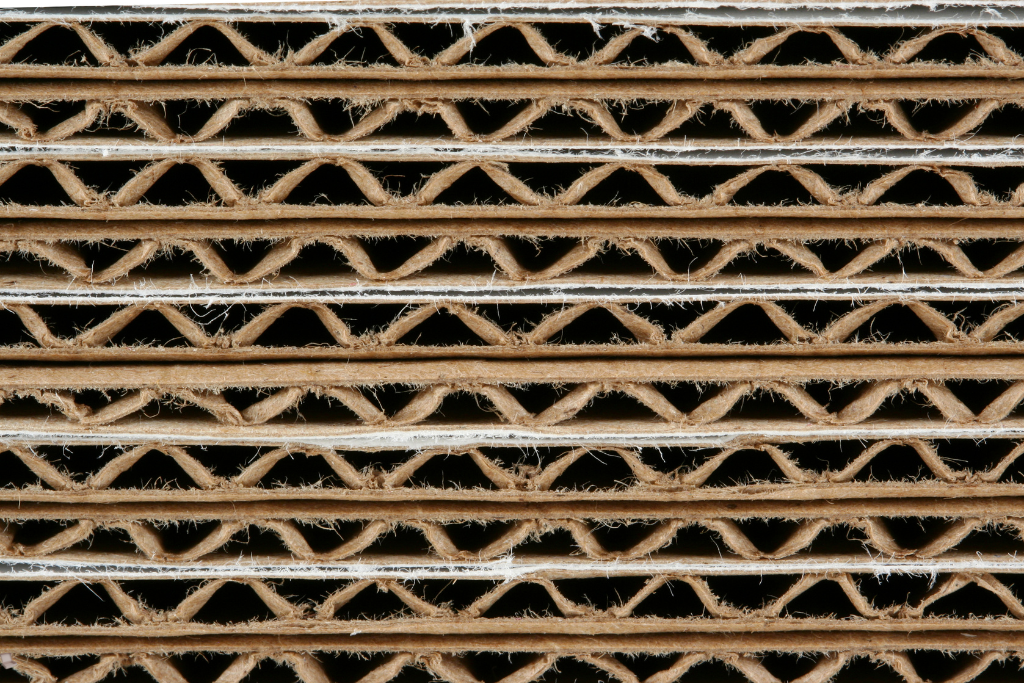

Unlike ordinary cardboard, corrugated boxes are made of different layers of cardboard on top of each other. Flat and fluted layers combine to make a structure that is both light and tough. Corrugated cardboard boxes are typically made up of three layers: two outer liners (flat sheets) enclosing a middle layer of fluted paper. Bonded together with strong adhesives, these layers form a rigid, protecting structure.

The fluting (the wave-like structure between paper liners) is at the heart of the corrugated box. The fluted layer serves as a shock absorber, and distributes the weight evenly across the box. If the box lacks this fluting, it loses a great deal of its strength, and is susceptible to damage by pressure or impact. Together, the outer liner and inner fluting make the box strong enough to withstand compressive and bending forces.

Why Fluting Matters in Corrugated Boxes

The fluting inside the corrugated boxes is not just for decoration—it plays a critical role in providing strength and rigidity. During the manufacturing process, the corrugated medium is formed by the wave pattern, usually this medium is formed by recycled paper. The material is anisotropic in its strength because it is strong in some directions but not others, and this wave-like structure is what gives it this property.

The strength of this anisotropic strength is good for shipping since boxes tend to be stacked on top of each other. The flutes stand vertically, giving weight over the whole surface and eliminating the chance of box collapsing under pressure. Additionally, the spaces between the flutes act as insulation, protecting the contents inside from temperature changes and physical shocks.

Different flute sizes are used for specific business purposes in corrugated boxes. The most common flute types are:

A-Flute: Excellent stacking strength and cushioning; great for fragile items.

B-Flute: Used for smaller packages, offers superior puncture resistance.

C-Flute: A versatile type with great stacking strength and a great cushioning.

E-Flute: Small boxes with thinner fluting to provide a smooth surface for printing.

F-Flute: Very fine flute size used for very lightweight items or small retail packaging.

The Impact of Box Design on Strength

The strength of corrugated boxes is determined by the type of fluting and the overall design. The ability of the box to withstand various stresses depends on how it is constructed, how it is folded, and how it is sealed. Key design factors include:

Single-wall, double-wall, and triple-wall construction:

Single wall box has one liner on both sides of a layer of fluting. Double-wall boxes have two layers of fluting and three liners for added strength, while triple-wall boxes have three layers of fluting and four liners. These variations enable manufacturers to vary the package strength as per the product being shipped, from lightweight products to heavy duty machinery.

Box dimensions and shape:

The strength of the box also depends on its size and shape. Square or rectangular boxes with even sides distribute weight more effectively, reducing the risk of one side giving way under pressure. Also, the dimensions of the box must hold the product, leaving no excess space, for a possibility of damage through movement in the box.

Edge Crush Test (ECT):

This test determines how much pressure a box can take until the edges cave a bit. The higher an ECT rating, the stronger the box is, with the ability to hold more weight. Heavy loads are best taken by boxes with a high ECT rating, as it provides the higher resistance to collapse.

Material Composition: The Science Behind Strength

The strength of corrugated box is not only due to its design and flute configuration, but equally depends on the quality of the materials. Kraft paper is the most common corrugated box material and it is made from softwood trees, such as pine. Softwood has a long fiber that makes for a dense, strong paper that can continue to endure the abuses of shipping and handling.

In addition, the fluted and liner papers are bonded together with an adhesive which assists to increase the strength of the box. Modern corrugated box manufacturers use eco-friendly adhesives derived from natural starches, further enhancing the sustainability of the product.

Another way to determine the box’s material integrity is a bursting strength test. The more pressure the box can take before bursting, the better this is. Boxes with high burst strength are great if you ship sharp or oddly shaped parts because they won’t rip or puncture the boxes.

Corrugated Boxes And Environmental Sustainability

Businesses are seeking sustainable packaging more and more in our increasingly eco-concious world. Corrugated boxes, often made from recycled materials, offer an environmentally friendly solution. Not only are they recyclable, but their production requires less energy and generates less waste than other packaging materials like plastic or metal.

Most corrugated boxes can be recycled several times before the fibers are too short for use. Manufacturers are also implementing responsible sourcing practices, so that materials sourced for manufacturing come from managed forests. In addition, lightweight corrugated boxes help reduce the overall weight of shipments, thereby reducing the amount of fuel used for transportation and the associated carbon footprint of shipments.

Testing for Durability: How Corrugated Boxes Are Evaluated

The corrugated boxes are put through rigorous tests to certify that they are capable of surviving shipping and handling. The two tests used to measure these boxes to evaluate their strength are the Edge Crush Test (ECT) and the Burst Test.

Edge Crush Test (ECT): This test measures the amount of force a box can support when stacked vertically. The ECT rating, expressed as pounds per inch of load bearing edge, is how manufacturers determine whether a box will support heavy loads without collapsing.

Burst Test: This is also called the Mullen Test and tests for the ability of the corrugated material to resist rupture under pressure. This is particularly valuable for products that could apply pressure to the box, such as sharp corners, or heavy items.

Both these tests provide valuable data to manufacturers, ensuring that the boxes they produce can safely protect their contents under real-world conditions.

Custom Corrugated Box Design for Specialized Needs

Standard corrugated boxes are good enough for most uses, but some industries need special designs. The addition of dividers, inserts, or reinforced corners are just some of the custom features that can be added to reference a specific product to be carried in a custom corrugated box design. For example, glassware or electronics can be fragile, so may need additional protection, whereas industrial equipment might need specially shaped boxes just so that it can fit securely.

This enables businesses to maximize the protection of their products without wasting material to guarantee protection. By designing a box that perfectly fits the item, manufacturers can reduce the need for excessive packaging materials, lowering both costs and environmental impact.

Conclusion

The strength of corrugated boxes lies not only in their multi-layered structure but also in the science behind their design. Every detail of corrugated box design—ranging from the choice of fluting and materials to careful testing to ensure durability—has made these boxes among the most dependable packaging solutions in the industry.

Caicheng Printing provides custom solutions for businesses that are seeking high quality and eco friendly packaging at reasonable prices. Having been in the packaging industry for years, Caicheng is a supplier that never compromises on sustainability and has very advanced production technology. No matter what you’re shipping, delicate items or bulky equipment, our corrugated boxes give you the strength, durability and customization you need to keep your products safe in transit.